METAL CENTER NEWS BUYERS GUIDE AD

Building relationships manufacturing quality. Ask how we can help reduce your spare parts expenditures.

METAL CENTER NEWS AD – MAY 2024

Revive your leveler’s performance! Unmatched reconditioning excellence.

IRON & STEEL TECHNOLOGY MAGAZINE – MAY 2024 AD

Next-Gen Innovation from Allor Manufacturing.

Iron & Steel Technology Magazine – April 2024 Ad

Allor’s Compact Pickle Line Straightener.

Iron & Steel Technology Magazine – March 2024 Ad

Next-Gen innovation from Allor Manufacturing.

Metal Center News Ad – February 2024

Allor specializes in engineering and manufacturing robust levelers tailored to meet your specific product requirements.

Iron & Steel Technology Magazine – February 2024 Ad

Are you looking for improved performance and increased productivity for your tension leveler application?

IRON & STEEL TECHNOLOGY MAGAZINE – AUGUST 2024 AD

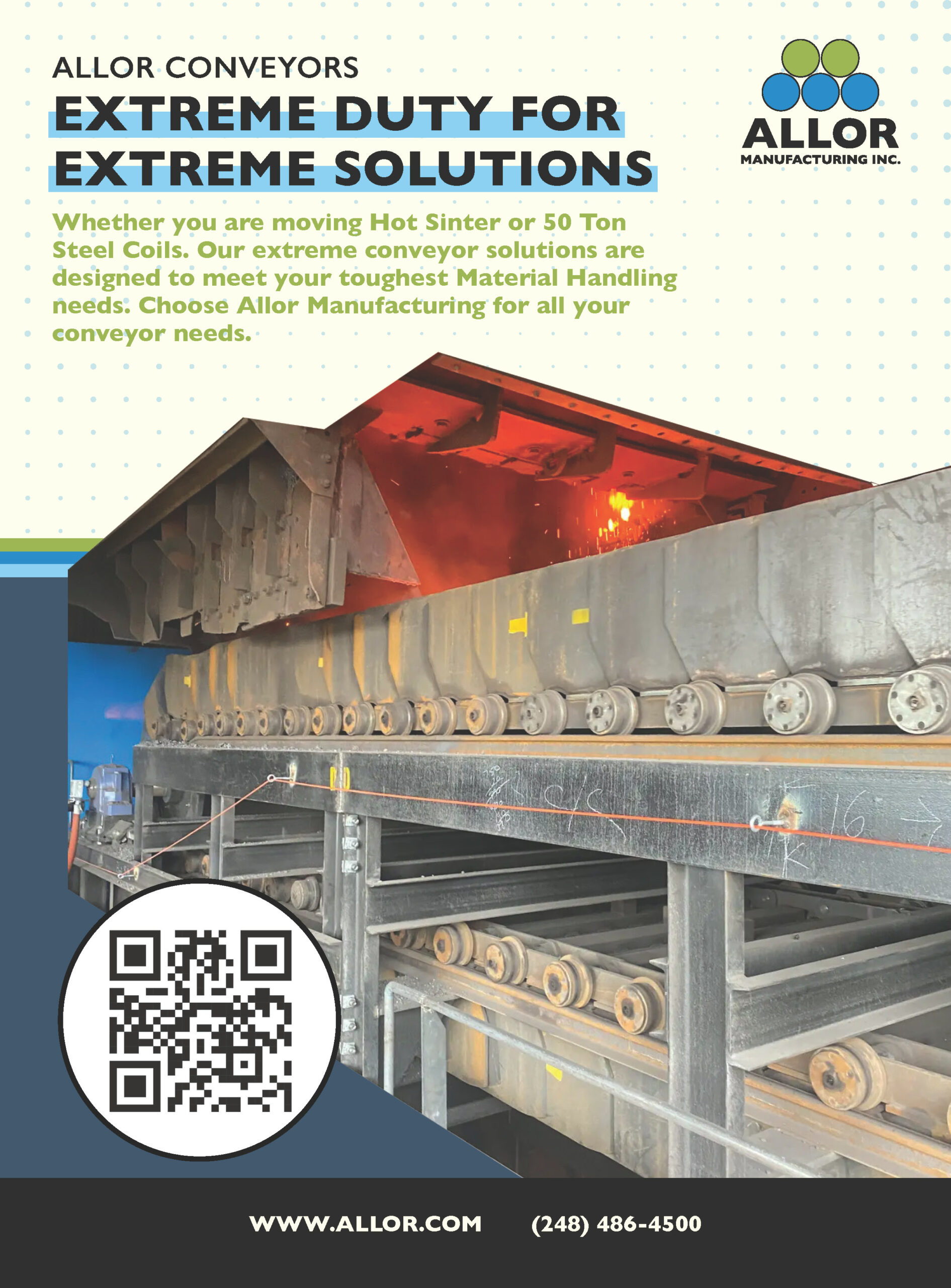

Whether you are moving Hot Sinter or 50 Ton Steel Coils. Out extreme conveyor solutions are designed to meet your toughest Material Handling needs.

Metal Center News Ad – May 2023

Did you see our latest ad in Metal Center News? Learn about our Automatic Cassette Changing Leveler

Iron & Steel Technology Magazine – May 2023 Ad

Did you see our latest ad in the Iron & Steel Technology Magazine featuring our Next Generation Tension Levelers?