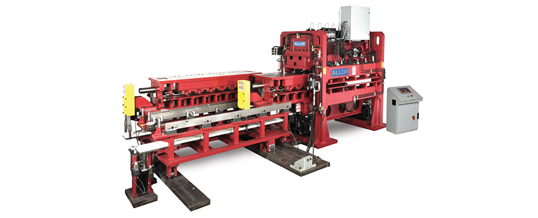

Allor Manufacturing Inc introduces our new Slitting Line Leveler providing leveling designed to meet our customer’s product needs.

The moveable lower platen provides variable roll plunges based upon gauge and yield strength settings entered by the operator via the machine HMI. Four hydraulic cylinders, each operated by proportional valves and LDT system automatically position the lower platen to the desired plastification settings. Roll bending via the upper backup bearing chocks correct localized defects such as cross bow, longitudinal bow, center buckle and edge wave. Roll bending is real-time and can be entered from existing saved programs or operator input.

A side-shift cassette change system allows for fast, hands free, cassette changing via the HMI. A spare cassette of the existing or an alternate roll configuration is on standby ready to install. The 4-HI machine has been configured to allow for optional 5-HI or 6-HI cassettes with no modification to the machine.

FEATURES:

- Four hydraulic cylinders automatically position the lower platen to the desired plastification settings.

- Moveable lower platen provides variable roll plunges based upon gauge and yield strength settings entered into the machine HMI.

- Roll bending via the upper backup bearing chocks correct localized defects such as cross bow, longitudinal bow, center buckle and edge wave.

- Side-shift cassette change system allows for fast, hands free, cassette changing.

- Spare leveling cassette of the existing or an alternate roll configuration is on standby ready to install automatically.

- 4-HI machine has been configured to allow for optional 5-HI or 6-HI cassettes with no modification to the machine.

OCT

2017